BGA Rework Station

BGA-935BL

High Performance‧Easy Operation

Easy operation and high performance is what BGA-935BL famous for. Equipped with outstanding nozzles and precise temperature control device, BGA-935BL is popular in RMA departments and Mobile Phone field.

3 minutes setup in microprocessor controller, BGA-935BL will precisely and accurately proceeds BGA soldering and desoldering work.

Powerful Function

Quick soldering and protect the components safety

-

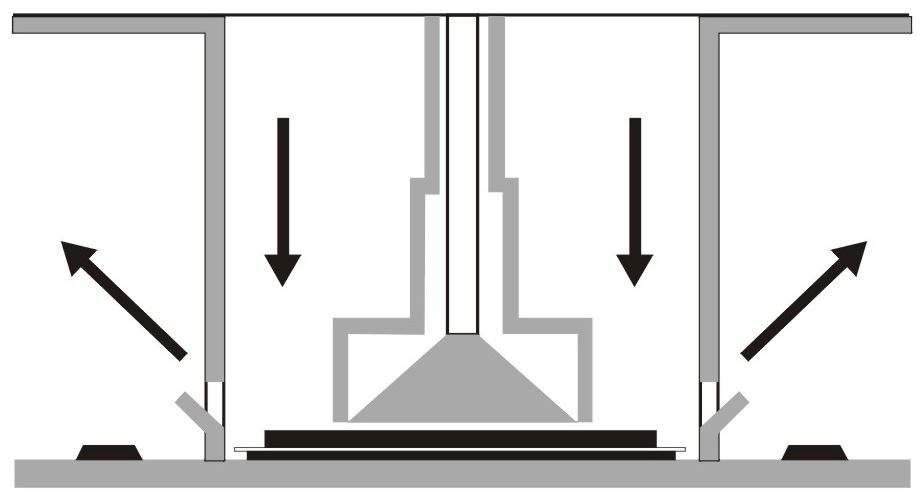

Sole design for adjustable hot air forcible guide (Patent No. 156948 & 135016).

-

Characteristic of high volume (250 l/min), low pressure (0.22kg/ cm2), low temp (220°C) rework completely guarantees BGA chips electricity and excellent soldering quality.

-

Utilization of silent and low pressure type air blower permit the regulation of silent ventilator, the air flow can be regulated to 250 l/Min the maximum.

-

Hot air multi-hole round center support is especially useful for big-size PCB and BGA located in the center of PCB. Avoid cold soldering and IC-drop situation.

-

Temperature profile of bottom hot air heater can reach as high as 300°C, critical for big size motherboard. Meanwhile, upper heater could be set as synchronized or independent work.

Utilization of hor air forcible guide, nozzle will match with PC

Utilization of hor air forcible guide, nozzle will match with PC

board while heating. Totally uninfluential to other components.

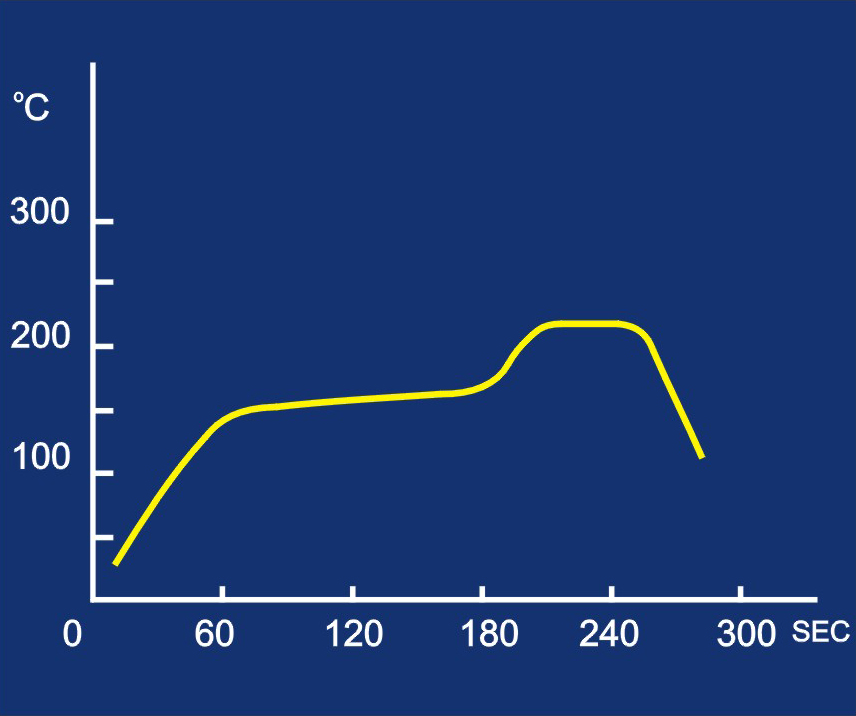

Programmable Temperature Control System makes Excellent Profile

-

Built-in itinerary reflow display permit clearly control the reflow condition. With vacuum pump, it can pull out the SMD automatically.

-

The temperature of hot air is stable and the temperature accuracy is at ± 0.1°C. There are two temperature units of °C and °F for choice. Equipped with three groups of PID value, a reference number can be programmed automatically, also can be memorized and stocked.

-

High speed feedback system, accurate hot air temperature memory.

Built-in programmable fuzzy hot air temperature and time

controlsystem permit the best obtaining of soldering profile

Durable Structure

-

The three XYZ shafts have the detailed regulation function or can locate quickly. The nozzle can be rotated freely with a range of 360°.

-

Main structure is an aluminum alloy with heat treatment, linear ball guide and painted with PP powder. Easy maintenance, durable utilization and beautiful appearance.

Specification

|

Main Voltage

|

220 ±10V AC

|

|

Power Consumption

|

Max. 2100W

|

|

Preset Temp. of Top

|

50 ºC ~ 399 ºC (122ºF ~ 750) ºF)

|

|

Top Heater

|

1000W

|

|

Air Spouting

|

250 l/min Max. (Adjustable)

|

|

Vacuum Pump

|

420mm Hg Max.

|

|

Working Light

|

50W 12V

|

|

PCB Size Capacity

|

450mm x 400 mm

|

|

Dimensions

|

45(W) x 55(H) x 60(D)cm

|

|

Weight

|

30kg

|

Accerrories

|

Hex key wrench

|

1 set

|

|

Vacuum pad (Ø10 Ø15)

|

1 pcs

|

|

Center Supporter

|

1 set

|

Optional Accessories

1. Complete range of standard and custom nozzles.

2. High-Resolution Color CCTV packages.

3. Gloves with high temperature resistance.

4. Monitor mount

5. Various sizes of vacuum pads. (Ø2, Ø5, Ø10, Ø15)

6. Clamper for special P.C. Board.